Top chain manufacturing brand with over 100 years of history

Top chain manufacturing brand with over 100 years of history

IZUMI CHAIN MFG. began operations in March 1916, and celebrated its 100th anniversary in 2015.

After the bubble burst, sales fell sharply and hiring stopped, making it a difficult time for the company. However, thanks to the strong belief of our management that we must protect jobs,

we managed to get through this without having to resort to restructuring even once. Even during difficult times, we have continued to develop and introduce automated equipment, sparing no effort in manufacturing, aiming to surpass the present.

We have built relationships of trust with the world's leading companies in the industry and have been able to continue business partnerships and collaborations for over half a century, which has led to our 100 years of success. Aiming for a further leap forward, Izumi Chain's Vietnam plant started mass production operation in July 2024. Using the Vietnam plant operation as a foothold, we will put into practice the expansion of global production/sales.

Four strengths that support Izumi Chain

Reliable quality

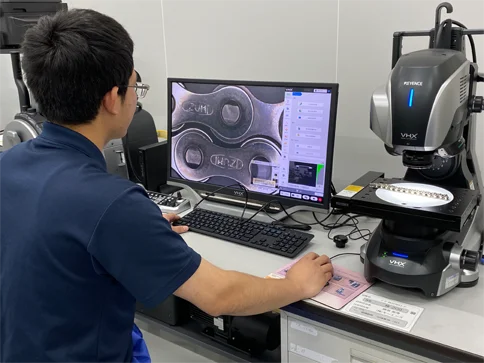

Chains function by being incorporated in a variety of applications, including machinery, equipment, bicycles, motorcycles, and more. To ensure the highest reliability and performance of the these devices, we invest significantly in cutting-edge inspection and measurement technologies, along with rigorous on-site quality assurance processes. Through the continuous improvements, we have steadily enhanced our product quality and strengthened our trust-based relationships with our customers. In recognition of our commitment to quality, we achieved ISO 9001 certification in 2010.

On the assembly line, various sensors are used to check dimensions and detect any missing or foreign parts to ensure the quality of the chains. The Quality Assurance department further guarantees product quality and performance with over 30 units of inspections and testing equipments. This includes 14 shape measurement devices, such as high-precision image measurement systems and contour measurement machines, as well as digital microscopes, tensile testing machines, and compression testing machines.

Manufacturing capabilities/technical capabilities

We do our best to meet the needs of our customers, the equipment manufacturers. When demand for bicycles increased worldwide due to the coronavirus pandemic, we responded to customer demands by creating a production environment that could withstand a significant increase in production.

In 2021, we will increase our production capacity by 1.5 times compared to 2020, and in 2022 we will increase our production capacity by 1.7 times.

We also design and manufacture special chains for industrial machinery, and our development, technology, and manufacturing departments work together to actively commercialize products with difficult specifications using the mobility that large companies lack. We are working on this. We have also established a system to flexibly respond to customer requests in conjunction with neighboring partner companies that have high technical capabilities.

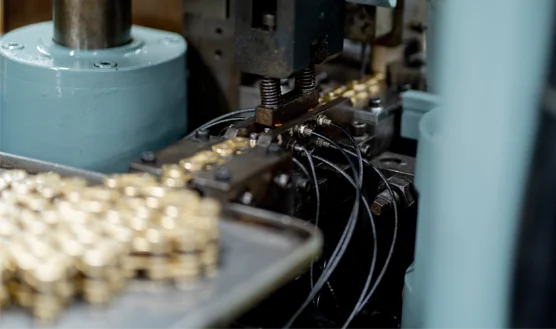

In-house integrated production system

We spare no effort in investing in production equipment to ensure high levels of Q (quality), C (cost), and D (delivery). Equipment related to forming plates and pins such as progressive forming presses and CNC automatic lathes, polishing equipment to polish metals to make them smooth, assembly machines that assemble chains from multiple parts, and heat treatment to optimize the mechanical properties of metals. In addition to over 330 production equipment such as furnaces, we have approximately 200 progressive plate molds and have built an integrated in-house production system.

In addition, we have built a system from prototype to mass production that utilizes these facilities.

Product development ability

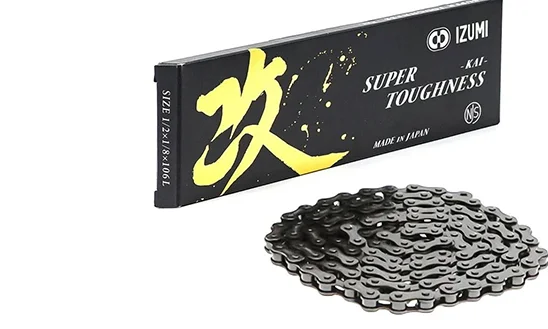

We have made repeated design improvements and improvements over the past years, and have created them using our high level of skill on-site to provide high-performance, high-quality bicycle chains.

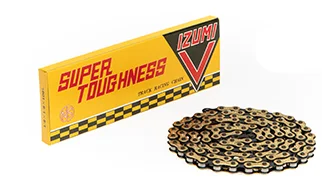

At Tokyo 2020, where top bicycle racers gathered, we were selected by many racers and produced many medalists. In particular, "IZUMI SUPER TOUGHNESS KAI", developed with the US national team, is one of the world's smoothest and strongest products. We received the best comment from a US truck representative: "The smoothest chain ever."