Process of manufacture of the chain

-

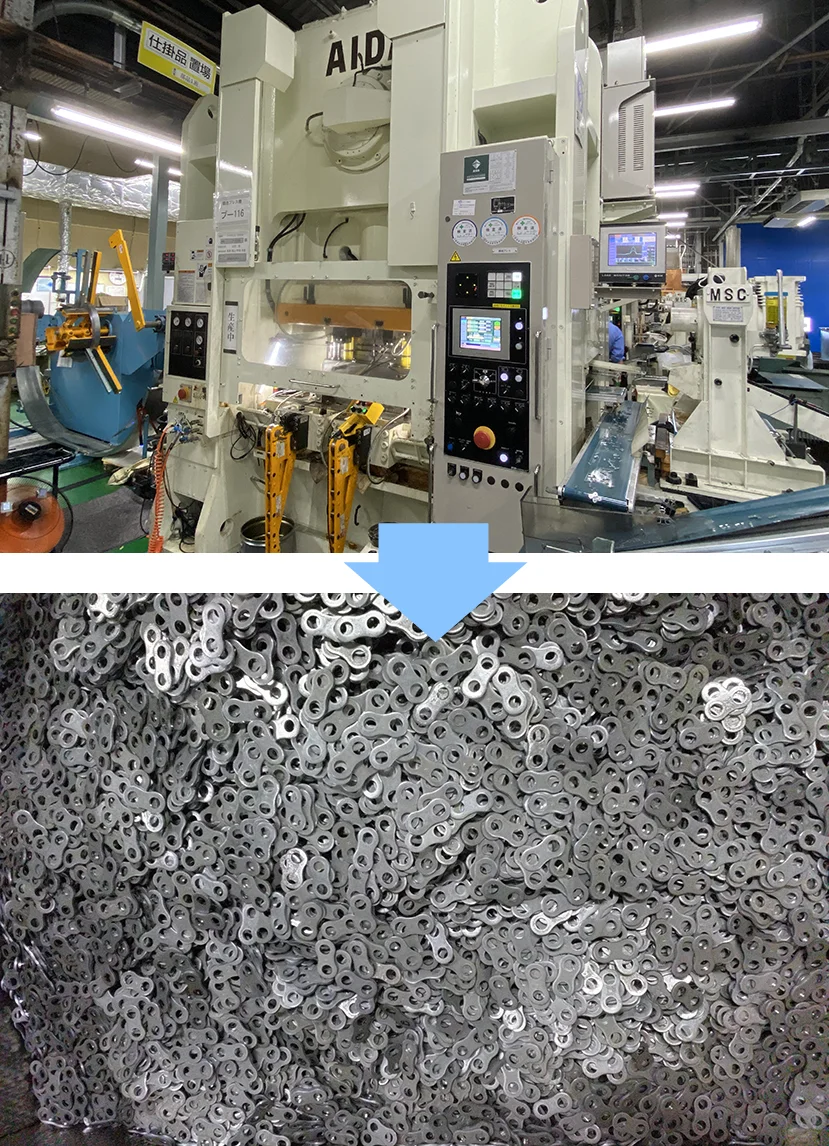

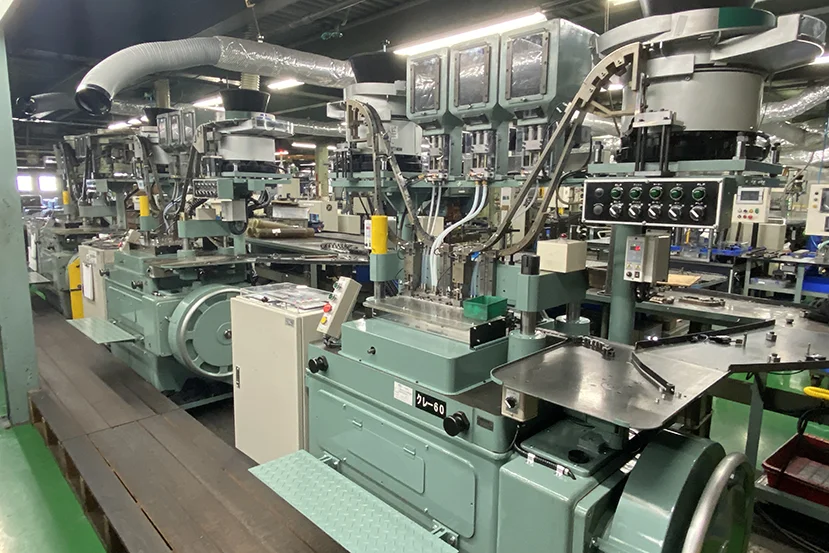

Molding of each part

In the part molding process, link plates (plate parts) and bushings, rollers and rivet pins (round parts) are molded with micron-level precision. In press molding, we use progressive dies and thorough automation in our relentless pursuit of quality and cost reduction. In 24-hour operation facilities, we perform daily quality checks and manage the facilities to achieve unmanned continuous operation without quality defects.

-

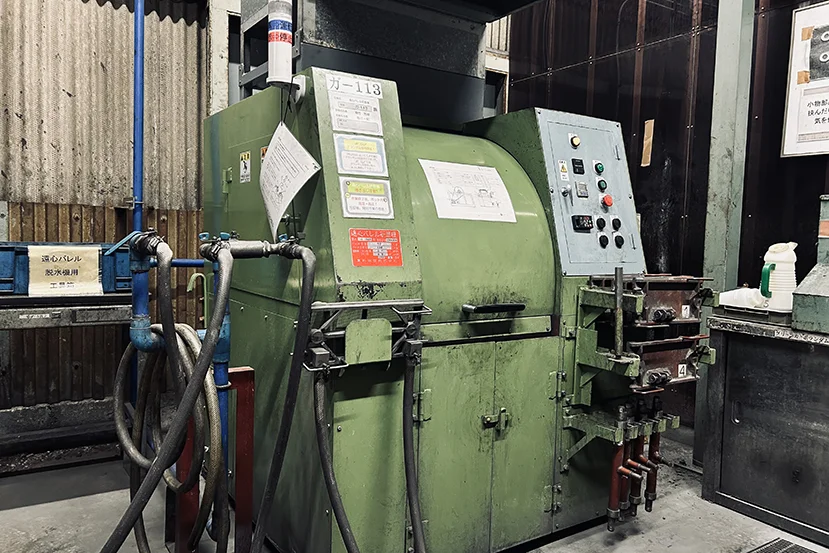

Washing (pre-processing)

In the washing process (pre-processing), large 400L tumblers and medias are used to remove oils, grease, and dirt from the products before they are heat treated. In addition to the cleaning process, there is also a

dimensioning

process, in which the pin diameter is adjusted, and achamfering

process, in which the ends of the bushings and pins are polished to create a rounded surface. We thoroughly manage dimensions to the micron-level of the products, and while we pursue quality, we are also thorough in carrying out our work safely. -

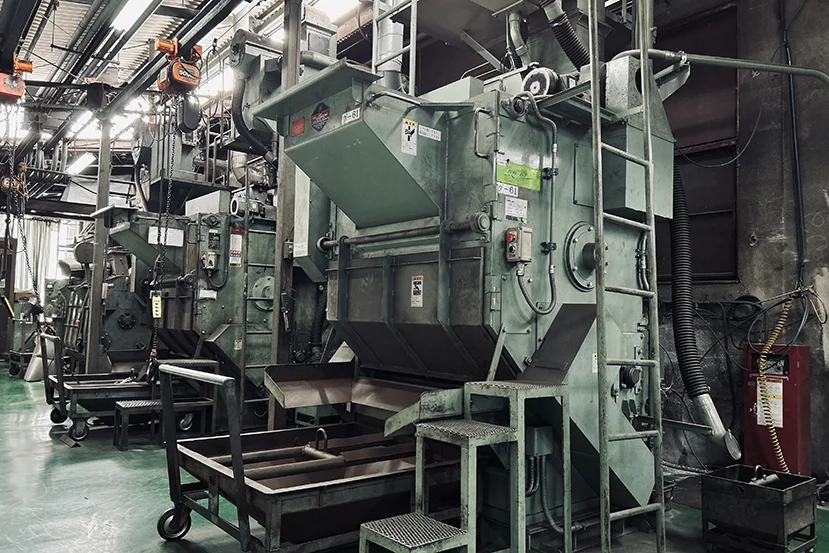

Heat treatment processing

We use large mesh-belt type continuous quenching and tempering furnaces, which enable us to produce large quantities of products of various materials. Because these equipments use a lot of energy, we inspect, maintain, and improve those in-house, managing them so that we can get the most out of the continuous furnaces, and focusing on safety, energy conservation, cost reduction, and quality improvement.

-

Parts finishing (post-processing)

The parts finishing process (post-processing) includes steps such as

polishing

,rust prevention

, anddescaling

performed on the product after heat treatment. Similar to the washing process (pre-processing), large 400L tumblers are used, but due to concerns about mixing of products before and after heat treatment, the process is conducted in separate work areas. Additionally, the process known asshot peening

is being adopted, which involves work hardening through plastic deformation and the application of compressive residual stress, aimed at enhancing the product's fatigue strength, wear resistance, and resistance to stress corrosion cracking. -

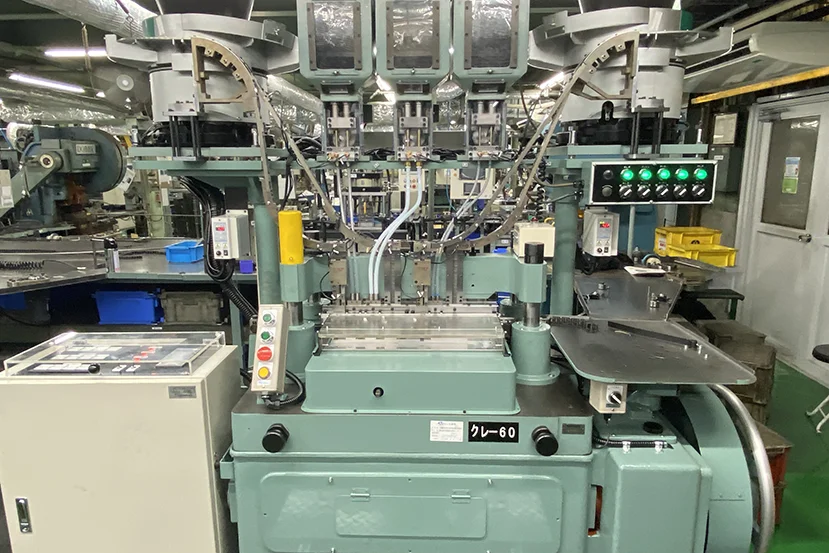

Assembly

In the assembly process, we understand the characteristics of each completed part and assemble with micron-level precision to meet our customer's requirements. We use a variety of machines to handle a wide variety of products and manufacture high-quality chains according to the design drawings. We pursue low cost and high quality by balancing the good points of machine and manpower. We also manufacture a wide variety of small lot products, such as joint links used as joints, offset links used for length adjustment, and products with attachments. We perform optimal assembly by hand or using the latest equipment to meet the products requested by our customers, and we strive every day to maintain and further improve our high quality.

-

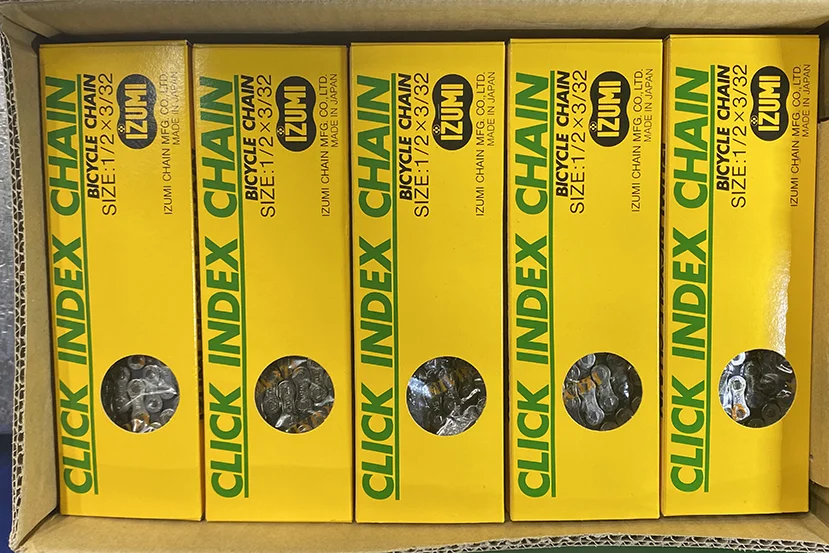

Finishing, Packaging and Packing

In the finishing, packaging and packing process, we finish, oil, dry, and package the chains according to our customer's request. In the finishing process, workers carefully perform assembly and inspection tasks that cannot be done by machine, one by one, resulting in a high-quality chain. We are also focusing on reducing costs by promoting automation in our packaging and packing lines.